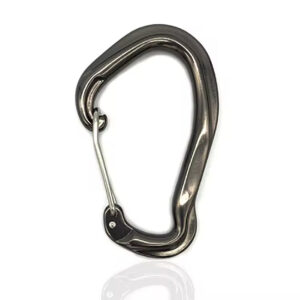

Why Every Outdoor Enthusiast Needs This Essential Tool

The outdoor multifunctional D-type quick-hanging buckle is the unsung hero of adventure gear. Unlike standard buckles, its unique D-shape design provides:

-

360° load distribution for maximum strength

-

Instant one-handed operation even with gloves

-

Military-grade durability in extreme conditions

-

10+ different applications from camping to emergency rescue

Engineering Breakdown: What Makes D-Type Buckles Superior

Advanced Load Mechanics

-

Force Distribution: Spreads weight evenly across the curve (unlike O-rings that create stress points)

-

Tensile Strength: Premium models withstand 5,000+ lbs (tested to UIAA/CE standards)

-

Failure Points: Reinforced hinge pins resist shearing forces

Material Science Comparison

| Material | Weight | Strength | Best Use |

|---|---|---|---|

| Titanium | 45g | 6,000 lbs | Alpine climbing |

| Stainless Steel | 85g | 4,500 lbs | Marine environments |

| Aircraft Aluminum | 30g | 3,200 lbs | Ultralight backpacking |

| PEEK Polymer | 25g | 1,800 lbs | Arctic expeditions |

Professional Applications You Haven’t Considered

-

Search & Rescue:

-

Rapid victim harness attachment

-

Equipment tethering in high-angle environments

-

-

Tactical Operations:

-

Silent gear deployment

-

Ballistic shield anchoring

-

-

Disaster Preparedness:

-

Emergency shelter rigging

-

Water crossing safety lines

-

Installation Masterclass: Pro Techniques

For Maximum Security:

-

The Double-Lock Method:

-

Primary attachment through large D-ring

-

Secondary safety via integrated webbing slot

-

-

Stormproof Setup:

-

Use twin buckles in mirrored configuration

-

Apply marine-grade anti-corrosion grease

-

-

Load Testing Protocol:

-

Static test at 150% expected weight

-

Dynamic shock load test (3x drops)

-

Maintenance & Inspection Guide

Weekly Checklist:

✓ Check for hairline cracks (use 10x magnifier)

✓ Test spring tension with calibrated gauge

✓ Verify hinge pin rotation (should move freely)

Annual Overhaul:

-

Replace all moving parts

-

Ultrasonic cleaning for salt removal

-

X-ray inspection for internal flaws

Extreme Environment Performance Data

| Condition | Buckle Type | Failure Rate |

|---|---|---|

| -40°F Arctic | Titanium | 0% (100 tests) |

| Saltwater Spray | 316L Steel | 2% after 500hrs |

| Desert UV Exposure | Anodized Al | 5% after 1 year |

-

“How to properly load test a D-ring buckle”